Company news

Basic knowledge of shackle

Summary

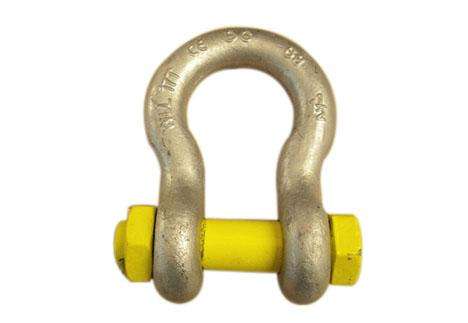

A kind of rigging shackle. The domestic market commonly used shackle, according to production standards are generally divided into American Standard, GB, the standard three class. One of the most commonly used American Standard because of its small size, large weight capacity and is widely used. According to the types can be divided into G209 (BW), G210 (DW), G2130 (BX), G2150 (DX). According to the type can be divided into the bow type (OMEGA bow shaped) with female shackle and D type (U type or D type straight type) with female shackles; by the use of places can be divided into the boat and land two. The safety coefficient is 4 times, 5 times, 6 times, even 8 times (such as the Swedish GUNNEBO super shackle). Its material, common carbon steel, alloy steel, stainless steel, high strength steel, etc.. Surface treatment is divided into galvanized (hot plating and electroplating, painting, plating dacrome) (Dacormet).

Rated load

The common market American Standard shackle the specifications for the 0.33T, 0.5T, 0.75T, 1T, 1.5T, 2T, 3.25T, 4.75T, 6.5T, 8.5T, 9.5T, 12T, 13.5T, 17T, 25T, 35T, 55T, 85T, 120T, 150T.

Scope of application

Shackle is widely used in electric power, metallurgy, petroleum, chemical, machinery, railways, ports, mines, construction and other industries.

Basic Requirements

1, shackle should be smooth, no crack, sharp edges, burning and other defects.

2, prohibited the use of cast iron or steel shackle. The button body can be used as a killed steel forging, and the shaft pin can be processed by the machine.

3, should not be in the shackle drilling or welding repair. After the deduction of the shaft and the shaft pin is permanently deformed, no repair may be performed.

4, when using, should check the button body and a bolt, without serious wear and deformation and fatigue crack.

5, the use of horizontal spacing shall not be affected by the tension, the pin must be inserted in the pin.

6, after the shaft pin is assembled correctly, the body width of the buckle body is not obviously reduced, and the thread connection is good.

7, shackle shall not exceed the safe load specified.

Inspection requirements

1, should be smooth and smooth, no cracks, sharp edges and over burning, etc., can be used to check the suspicious areas and other means of a magnifying glass.

2, to two times the safe load as the shackle test load test. The shaft pin must not be permanently deformed, and can freely rotate after twisting. The increment of the size of the button body length shall not exceed O.25% or O.5mm. 300 tons less than 2 times the safety load test load as the test, more than 300 tons for 1.33 times the safety load as the test load test.

3, shackle may sample reliability test. Load is two times the test load. No deformation fracture or shackle shackle loss of bearing capacity.

4, the safety load of shackle by M (4) level approval.

5, in the buckle body should be marked on the intensity level, safety load, etc..

Scrap requirement

1, there is a significant permanent deformation or shaft pin can not rotate freely.

2, buckle and shaft pin any section of the wear amount of the original size of more than 10%.

Crack 3, shackle any.

4, can not lock shackle.

5, after the test of unqualified shackle.